Top Hung Sliding Doors

C4G hung sliding doors providing more durability and long life. These hanger doors suitable for all sizes of door opening. Wide range of different appearance as single skin and double skin insulated panels. Sliding hung doors are hung from a horizontal top running track and are guided using a channel set into the floor. The top hung sliding doors are absolutely smooth in operation & sturdy against high wind pressure. No accumulation of dust and dirt on the track.

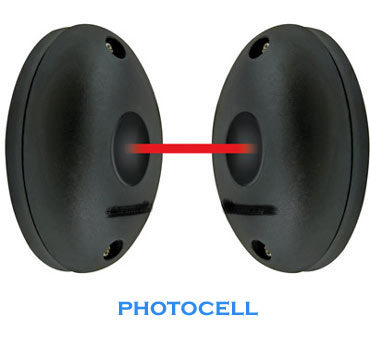

The door leaves are fabricated to suit the project and range from lightweight steel frames to structural steel leaves where the door is to form a large part of the building structure or wall. These doors are available as Motorized operated with Top or Bottom mounted Italian or Indian make motorized system operation including safety edges and photocells. These hung doors specially designed high precision rollers & bearings. Highly impact resistant and corrosion proof.

C4G sliding doors are excellent for large openings and ideal for creating that unique look with a wide range of cladding options. They are ideal for industrial & high rise project applications such as industries & factories. C4G have been producing sliding door and in that time have developed a reputation for high quality gear at highly competitive prices. We use high grade galvanised strip for the rails, with grease packed ball bearings to ensure smooth operation with minimum wear on the components. Height adjustment is easily done through adjustment built into the hanging brackets, eliminating the need to drill the door. All door gears & zinc electroplating process components is carefully thought through to make it easy for you to install. C4G sliding door gears & zinc electroplating process components includes bottom tracks to ensure straight running of your sliding door, and improved weather resistance.

“C4G Industrial doors benefit from many unique features and are individually specified, manufactured, installed and maintained to ideally suit your individual needs. Our industrial sliding doors are produced using only top quality materials, electric operator system and components, alongside advanced production techniques to ensure total customer satisfaction, year, after year, after year”

-

Track sections are cold rolled from high grade galvanised or steel strip and are supplied in four sizes in standard lengths

-

Support brackets, designed for side or top fixings and for single or double track runs

-

Continuous runs of track are formed by butt-joining several lengths, using a track support bracket and welded bracket at each joint

-

Door hangers are in various designs to suit door construction. Hangers have grease packed ball bearings and alloy wheels to ensure long life and smooth running

-

Vertical adjustment is incorporated in the hanger body, avoiding the need to drill the door

-

Wicket door for easy access may be incorporated into a sliding door

-

Designed to accommodate for different industrial building designs, doors can slide to one or both sides

-

At each end, a track stopper is placed to absorb any impact and to hold the door in the open or closed position

-

Additional guides at the bottom prevent the door from oscillation

-

Interlocking facility between two doors

-

Doors can be constructed with vertical EPDM rubber seal to prevent dust and provide complete sealing

-

The C4G sliding door gear range is designed for continuous hard wearing use with sliding doors up to 3000Kgs

-

A total safety system, automatic sliding doors are designed to meet all operational & safety needs

-

Unlimited widths for manually operated ‘push along’ doors

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

These sliding doors can be locked in open or closed position

-

Control to stop anytime while garage door is moving

-

Infrared sensor system reverses the direction of the door if any obstruction cuts across the invisible light beam

| Mounting Location | |

| Technical Specification | Description |

| Product | Motorized Sliding Doors |

| Door Type | Single side / Bi-parting Type |

| Door Mounting | On Top Track Mechanism |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Opening Direction | Horizontal |

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

Photosells

Push Button

Remotes

Computer

Flashing light