Motorised Telescopic Sliding Doors

C4G Industrial telescopic doors are perfect for sites where the back-run is restricted. Industrial telescopic doors can be made with up to 5 sections, and can reduce the run back required by 80%, compared to a single leaf gate. Each telescopic garage doors panel will move at a different speed so that the final position is reached simultaneously, operated by specially design telescopic mechanism. The telescopic doors can be personalized and are manufactured to specific site requirements; they are suitable for heavy duty applications. To achieve the maximum clear opening where the run back is very restricted, the telescopic garage doors is ideal.

Telescopic door is the natural choice for narrow industrial entrance ways as it maximises the width of the door opening providing a elegant solution when space is limited. Its precise design makes this solution suitable for places with high traffic, such as where shopping trolleys are entering and leaving. C4G can be door-height/front/multi-directional adjustable. Simple and easy installation.

C4G have been producing sliding door and in that time have developed a reputation for high quality gear at highly competitive prices. We use high grade galvanised strip for the rails, with grease packed ball bearings to ensure smooth operation with minimum wear on the components. Height adjustment is easily done through adjustment built into the hanging brackets, eliminating the need to drill the door. All door gears & zinc electroplating process components is carefully thought through to make it easy for you to install. C4G sliding door gears & zinc electroplating process components includes bottom tracks to ensure straight running of your sliding door, and improved weather resistance.

“C4G Industrial doors benefit from many unique features and are individually specified, manufactured, installed and maintained to ideally suit your individual needs. Our industrial sliding doors are produced using only top quality materials, electric operator system and components, alongside advanced production techniques to ensure total customer satisfaction, year, after year, after year”

-

High opening and closing speed as compared to other sliding doors

-

Available as motorized operated with bottom mounted Italian make motorized system.

-

Heavy duty bottom track & top mounted guiding track for sliding operation of the door.

-

Bottom roller assembly& top track roller bracket assembly designed for linear motion & top support for the door.

-

Wicket door for easy access may be incorporated into a sliding door

-

Perfect opening solution of partial sliding (single side or bi parting) of door panels can be decided on the actual space available for door parking.

-

At each end, a track stopper is placed to absorb any impact and to hold the door in the open or closed position

-

Additional guides at the bottom prevent the door from oscillation

-

Interlocking facility between two doors

-

Doors can be constructed with vertical EPDM rubber seal to prevent dust and provide complete sealing

-

The C4G sliding door gear range is designed for continuous hard wearing use with sliding doors up to 3000Kgs

-

A total safety system, automatic sliding doors are designed to meet all operational & safety needs

-

Unlimited widths for manually operated ‘push along’ doors

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

These sliding doors can be locked in open or closed position

-

Control to stop anytime while garage door is moving

-

Can be designed in 2 to 3 leafs for single slide motion.

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

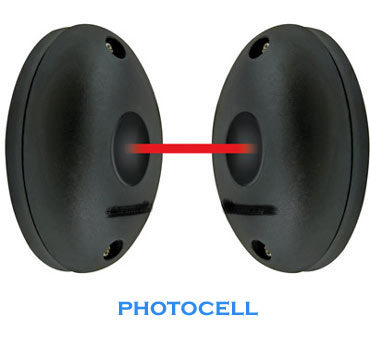

Optical beam sensor: Safety device to detect presence of vehicles and reversal of gate movement

-

It can be integrated with any kind of access controller system i.e. RFID device, Fingerprint and Biometric devices, Remote, card dispenser and Push button etc…

| Mounting Location | |

| Technical Specification | Description |

| Product | Motorized Sliding Doors |

| Door Type | Single side / Bi-parting Type |

| Door Mounting | On Top Track Mechanism |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Opening Direction | Horizontal |

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

Photosells

Push Button

Remotes

Computer

Flashing light