Automatic Dock Levelers

The C4G dock levelers for loading bays are the perfect connection between your warehouse and the loading vehicle. Loading and unloading becomes more fluid and risks to operators and goods are considerably low. Dock levelers are used to make easy loading and unloading of your goods in vehicles. It is made in different standard measurements with an epoxy painted finish to adapt to any facility. The structure is designed to withstand specific loads above nominal and accepts differences in the transverse level of the vehicle of up to 10 centimeters.

We offer a wide range of dock levelers, lifts and loading bridges, our dock levelers are easy to deploy and based around your daily business for example building design, traffic intensity, type of vehicles, bed heights, airports, shopping malls, hospitals, hotels and the handling equipment used for loading and unloading.

Dock levelers are also known as dock boards or dock plates. Dock levelers can enhance safety and productivity on the dock through a variety of design features. Different types of levelers are appropriate for different industries and/or different operations.

-

Dock Levelers are devices used to bridge the gap between the loading dock and the truck, during loading/unloading.

-

Most Truck trailers come with bed heights either above or below the dock.

-

The Dock Leveler moves up and down to meet the truck bed height so that forklifts and other work trucks can move smoothly in and out of the truck.

-

Durable, long lifespan and Low maintenance

-

Push button operation eliminates manual lifting

-

Anti skid chequered platform to avoid any accidents.

-

Our edge-of dock levelers are an effective, affordable alternative to portable plates.

-

This loading dock leveler mounts to the face of the dock to make loading and unloading trailers easier, and is ideal for medium traffic loading docks.

-

Field-proven industrial hold-down mechanism

-

Separate hydraulic cylinders are provided, two for dock movement & one for lip ovement ensures safe , sturdy operation.

-

The Dock levelers has Mechanical Safety device for inspection and maintenance operations.

-

Integration with existing shutters, sectional doors & other accessories to have smooth, safe operations.

-

Welded steel members maximize deck strength and improve product longevity

-

Hydraulic deck cylinders increase operating efficiency and reduce maintenance requirements.

-

Integration with existing shutters, sectional doors & other accessories to have smooth, safe operations.

-

Rubber bumpers are fixed at the front side of Dock Levelers to prevent damage of it’s structure

-

In case of power failure, the Dock Leveler will remain at the current position

-

Open lug-style front lip hinge for superior strength and extended life.

-

Three series of activation systems are available, including: mechanical (manual) operation, air-powered operation and hydraulic operation.

-

Optimum safety, user-friendly & energy efficient.

| Mounting Location | |

| Technical Specification | Description |

| Product | Motorized Sliding Doors |

| Door Type | Single side / Bi-parting Type |

| Door Mounting | On Top Track Mechanism |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Opening Direction | Horizontal |

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

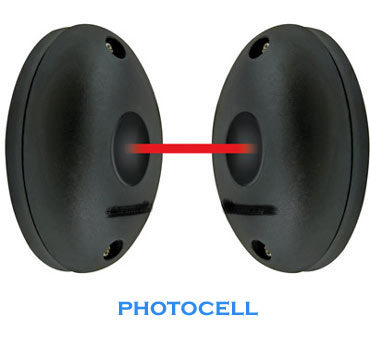

Photosells

Push Button

Remotes

Computer

Flashing light