Motorised Cantilevr Sliding Gates

Trackless sliding gate systems do not require a ground track – this can be advantageous where the driveway entrance slopes, busy or heavy traffic entrances or where minimal disturbance to the driveway surface is requested. The main design difference from a tracked system is that the cantilever system has a special section bottom rail in which incorporates two sets of enclosed roller wheels set apart at a pre- determined distance to a large concrete foundation base.

The cantilever sliding gate is approx 1/3 longer than a tracked slider, the extra length acts as a counterbalance so that the gate is free to slide back and forth, supported throughout the entire opening/closing width by the roller wheels within the bottom rail. There is a slam post assembly at one end and stops at the other end to ensure that the gate cannot slide free of it mountings and fall over. Often the lower leading edge has a wheel which engages into a guide/shoe to ensure correct engagement upon closing.

The gate is held up-right by a guide rail and a roller. Guides positioned at the mid or top rail height. In the manual mode the gate is very easy to slide open and closed as the roller wheels incorporate precision bearings. The method of automation is based on a rack and pinion principle, the motor unit has a drive gear which engages into a linear rack positioned on the lower inside face of the gate, the motor gear wheel simply drives the gate open and closed.

-

Gate is designed to operate without bottom rollers on gate.

-

Gate opens and closes suspended. Gate suspended by means of a cantilever system.

-

Automatic Cantilever Sliding Gates are virtually maintenance free as there is no accumulation of dust & water on the track.

-

Cantilever gate manufacturers use ( Imported or Indian ) make cantilever track and pair of bottom trolley rollers.

-

In case of power failure -just unlock device with personalized key

-

no trace on the ground and no danger lane changes because of the climate of the bend.

-

no risk of wear or bending due to the passage of trucks or heavy vehicles.

-

Works on Precise machine cut toothed pinion along with galvanized rack arrangement

-

These types of doors in cantilever sliding doors can be easily installed on an unsterilized floor, or perfectly horizontally.

-

Electromechanical gear motors range: 400 to 6000Kg for heavy gate application

-

Available with hinged side & inbuilt wicket gates for pedestrian use.

-

Heavy duty cantilever rolling gear.

-

High quality rollers to reduce noise and vibration

-

Custom designed as per clients requirements

-

Gates can be interlocked with entrance boom barrier as additional safety.

-

Sand blasting, hot deep galvanizing process, painting can be provided.

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

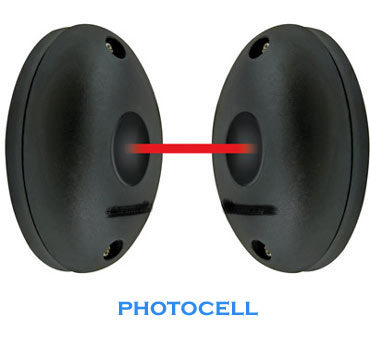

Optical beam sensor: Safety device to detect presence of vehicles and reversal of gate movement

-

It can be integrated with any kind of access controller system i.e. RFID device, Fingerprint and Biometric devices, Remote, card dispenser and Push button etc…

PRODUCT |

Motorised Telescopic Sliding Gates |

||

GATE DIMENSION |

|||

| Width Min./Max. | Single Leaf : 1200/16000mm Double Leaf :2200/32000mm |

||

| Height Min./Max. | 1000/2700mm Larger Dimension on request |

||

| Opening Direction | Horizontal | ||

| Mounting Location | Inside/ Outside | ||

| Mounting Surface | Bottom Rail: RCC Columns : RCC |

||

GATE STRUCTURE |

|||

| Outer Frame | Heavy Duty tubular box section (or Customized design available on request) |

||

| Internal vertical member | Heavy Duty Vertical Box sections (or Customized design available on request) |

||

| Bottom Rollers | European make and Indian make high performance dual pattern hangers equipped with noiseless ball bearings | ||

| Pattern | Standard Mild Steel Tubular pattern | ||

| Full height Column | Heavy Duty Box Section (or Customized design available on request) |

||

| Cantilever Track | European make imported make and Indian make Cantilever Track | ||

| Guide Rollers | Nylon Rollers with bearings both side mounted on column for support & smooth movement of gate. | ||

PATTERNS/DESIGNS |

|||

| Other available gate material | Stainless Steel, Hot dip Galvanized Steel, Mild Steel, Aluminium Steel |

||

| Sheets | M.S/GI/Perforated /Aluminium sheets Polycarbonate / Acrylic / PVC Sheet/Glass/Wood/WPC Wood/Fundermax panels |

||

| Ornamental Designs | On Request or as per client or architect design. | ||

| Options Available | Spikes as per requirement Wicket gate/Side Gates in the similar pattern as the main gate Any type of Customized Design can be made on request. |

||

FINISH |

|||

| Surface Finish | Surface preparation:-Sand Blasting Standard: Primer Finish Optional: Enamel Painting/Duco/PU painting/ Powder coating/ Hot deep Galvanising |

||

DETAILS FOR AUTOMATION SYSTEM |

|||

| Drive Unit | Imported & Indian make electromechanical drive having features such as powerful startup & thermal sensors Single( A.C & D.C )/Three Phase |

||

| Emergency Operation | Manual release knob | ||

| Accessories (Optional) |

|

||

| Features | Interlocking with existing boom barriers if required | ||

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

Photosells

Push Button

Remotes

Computer

Flashing light